MindMap Gallery Methods for observing the composition of compounds

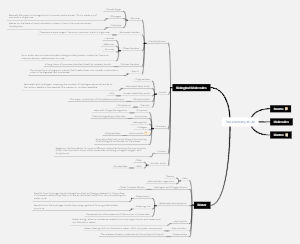

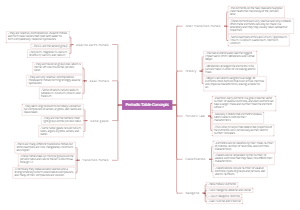

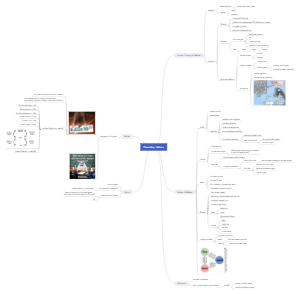

Methods for observing the composition of compounds

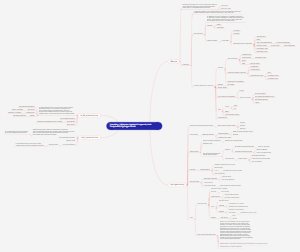

Methods for observing the composition of compounds encompass spectroscopy, X-ray crystallography, and thermal analysis. Spectroscopy includes UV-Visible Spectroscopy and NMR Spectroscopy to determine the chemical structure and functional groups of compounds. X-ray crystallography utilizes single-crystal X-ray diffraction and polycrystalline X-ray diffraction to reveal the crystal structure and atomic arrangement of compounds. Thermal analysis involves thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) to study the thermal stability and thermal effects of compounds.

Edited at 2024-12-11 09:24:38Methods for observing the composition of compounds

- Recommended to you

- Outline