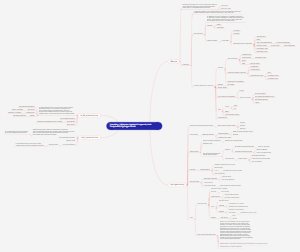

MindMap Gallery Photochemical reaction

- 6

Photochemical reaction

Substitution in photochemical reactions is a type of chemical reaction initiated by light, including radical substitution and addition-elimination substitution. When molecules absorb light energy, it is converted into chemical energy, driving the substitution reaction. These light-induced substitution reactions have specific mechanisms and pathways, leading to diverse chemical products.

Edited at 2024-12-22 09:46:55- Compound: How to use elastin

In the introduction section, elastin is a protein that plays a crucial role in the body, endowing tissues with elasticity and toughness. Its properties include high elasticity and good ductility. Elastin has a wide range of sources and is commonly found in animal connective tissues such as skin and blood vessels. When using elastin in products, the amount and method of addition should be determined based on the characteristics of the product. It has many uses and can be added to skincare products to enhance skin elasticity and reduce wrinkles; Improving food texture and enhancing taste in the food industry; In the medical field, it can be used to make elastic scaffolds such as artificial blood vessels, providing support for tissue repair. Reasonable use can play its unique value.

- Compound: Instructions for using protein

This document aims to guide the proper use of proteins. Proteins are the fundamental substances that make up life and are essential for maintaining normal physiological functions in the body, with a wide variety of types. When using protein, daily diet is an important source, such as meat, eggs, etc., which are rich in high-quality protein. Measuring protein intake can be done using professional tools or methods to ensure that the intake meets the body's needs. When mixing protein powder, it should be prepared according to the recommended ratio, and the water temperature should not be too high to avoid damaging the protein activity. Different groups of people have different protein requirements, such as athletes and fitness enthusiasts who can increase their intake appropriately to meet the needs of body repair and muscle growth.

- Compound: Usage of Unsaturated Polyester Resin

Introduction to Unsaturated Polyester Resin: It is an important thermosetting resin with various excellent properties. It has a wide range of applications and is used in the construction industry to produce fiberglass products such as doors, windows, decorative panels, etc; Used in the automotive industry for manufacturing body components. The advantages of use include simple molding process, low cost, and chemical corrosion resistance. However, it also faces challenges and limitations, such as relatively poor heat resistance and susceptibility to aging. During use, corresponding protective measures should be taken according to specific application scenarios, such as adding heat-resistant agents, antioxidants, etc., to extend their service life and fully leverage their advantages.

Photochemical reaction

- Compound: How to use elastin

In the introduction section, elastin is a protein that plays a crucial role in the body, endowing tissues with elasticity and toughness. Its properties include high elasticity and good ductility. Elastin has a wide range of sources and is commonly found in animal connective tissues such as skin and blood vessels. When using elastin in products, the amount and method of addition should be determined based on the characteristics of the product. It has many uses and can be added to skincare products to enhance skin elasticity and reduce wrinkles; Improving food texture and enhancing taste in the food industry; In the medical field, it can be used to make elastic scaffolds such as artificial blood vessels, providing support for tissue repair. Reasonable use can play its unique value.

- Compound: Instructions for using protein

This document aims to guide the proper use of proteins. Proteins are the fundamental substances that make up life and are essential for maintaining normal physiological functions in the body, with a wide variety of types. When using protein, daily diet is an important source, such as meat, eggs, etc., which are rich in high-quality protein. Measuring protein intake can be done using professional tools or methods to ensure that the intake meets the body's needs. When mixing protein powder, it should be prepared according to the recommended ratio, and the water temperature should not be too high to avoid damaging the protein activity. Different groups of people have different protein requirements, such as athletes and fitness enthusiasts who can increase their intake appropriately to meet the needs of body repair and muscle growth.

- Compound: Usage of Unsaturated Polyester Resin

Introduction to Unsaturated Polyester Resin: It is an important thermosetting resin with various excellent properties. It has a wide range of applications and is used in the construction industry to produce fiberglass products such as doors, windows, decorative panels, etc; Used in the automotive industry for manufacturing body components. The advantages of use include simple molding process, low cost, and chemical corrosion resistance. However, it also faces challenges and limitations, such as relatively poor heat resistance and susceptibility to aging. During use, corresponding protective measures should be taken according to specific application scenarios, such as adding heat-resistant agents, antioxidants, etc., to extend their service life and fully leverage their advantages.

- Recommended to you

- Outline

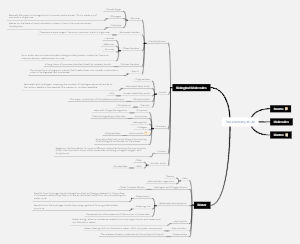

Photochemical reaction

Definition

Chemical reaction initiated by absorption of light

Involves the transformation of energy from light into chemical energy

Types of Photochemical Reactions

Primary photochemical processes

Excitation

Absorption of a photon

Electron promotion from ground state to excited state

Fluorescence

Emission of light as electron returns to lower energy level

Phosphorescence

Delayed emission of light after excitation

Internal conversion

Energy transfer without light emission

Intersystem crossing

Change in spin multiplicity during electron transition

Secondary photochemical processes

Radical reactions

Formation of radicals from excited molecules

Chain reactions involving radicals

Energy transfer reactions

Transfer of excitation energy to other molecules

Sensitized reactions

Laws Governing Photochemical Reactions

GrotthussDraper law

Only absorbed light can cause a photochemical reaction

StarkEinstein law

One molecule is activated for each photon absorbed

BunsenRoscoe law

Photochemical effect is proportional to the total light intensity and exposure time

Applications of Photochemical Reactions

Photography

Lightsensitive materials undergo changes to form images

Synthesis of chemicals

Production of pharmaceuticals, dyes, and other compounds

Environmental processes

Photodegradation of pollutants

Ozone formation and destruction

Biological systems

Photosynthesis in plants

Vision in animals

Factors Affecting Photochemical Reactions

Light intensity

Higher intensity can increase reaction rate

Wavelength of light

Specific wavelengths can trigger specific reactions

Concentration of reactants

Higher concentrations can lead to more frequent collisions and reactions

Presence of catalysts

Catalysts can alter reaction pathways and increase efficiency

Safety Considerations

Handling of lightsensitive chemicals

Proper storage and use of lightprotected containers

Eye protection

Wearing safety goggles to prevent eye damage from UV or visible light

Skin protection

Avoiding skin exposure to harmful wavelengths of light

Ventilation

Ensuring adequate ventilation to avoid inhalation of toxic vapors or gases