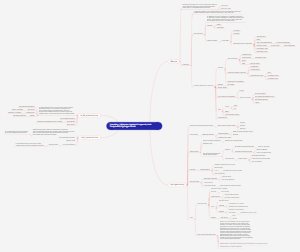

MindMap Gallery Lubricant decomposition

- 26

Lubricant decomposition

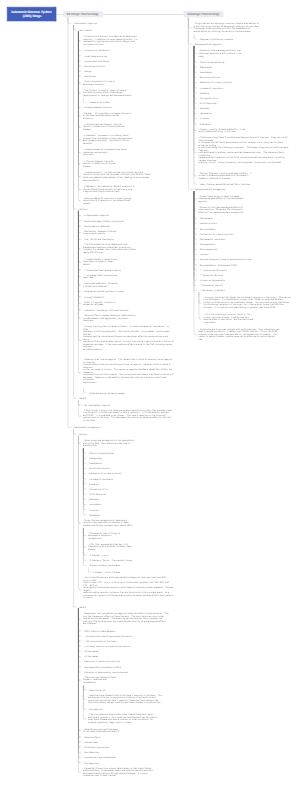

Lubricant decomposition refers to the process where the chemical structure of lubricants undergoes changes and their performance gradually declines due to factors such as high temperature and oxidation. This decomposition can be caused by various reasons including high-temperature working environments, oxidation, water contamination, and metal catalysis, leading to increased equipment wear, reduced lubrication performance, and in severe cases, the formation of sludge that affects the normal operation of equipment.

Edited at 2024-12-17 07:06:42- Compound: How to use elastin

In the introduction section, elastin is a protein that plays a crucial role in the body, endowing tissues with elasticity and toughness. Its properties include high elasticity and good ductility. Elastin has a wide range of sources and is commonly found in animal connective tissues such as skin and blood vessels. When using elastin in products, the amount and method of addition should be determined based on the characteristics of the product. It has many uses and can be added to skincare products to enhance skin elasticity and reduce wrinkles; Improving food texture and enhancing taste in the food industry; In the medical field, it can be used to make elastic scaffolds such as artificial blood vessels, providing support for tissue repair. Reasonable use can play its unique value.

- Compound: Instructions for using protein

This document aims to guide the proper use of proteins. Proteins are the fundamental substances that make up life and are essential for maintaining normal physiological functions in the body, with a wide variety of types. When using protein, daily diet is an important source, such as meat, eggs, etc., which are rich in high-quality protein. Measuring protein intake can be done using professional tools or methods to ensure that the intake meets the body's needs. When mixing protein powder, it should be prepared according to the recommended ratio, and the water temperature should not be too high to avoid damaging the protein activity. Different groups of people have different protein requirements, such as athletes and fitness enthusiasts who can increase their intake appropriately to meet the needs of body repair and muscle growth.

- Compound: Usage of Unsaturated Polyester Resin

Introduction to Unsaturated Polyester Resin: It is an important thermosetting resin with various excellent properties. It has a wide range of applications and is used in the construction industry to produce fiberglass products such as doors, windows, decorative panels, etc; Used in the automotive industry for manufacturing body components. The advantages of use include simple molding process, low cost, and chemical corrosion resistance. However, it also faces challenges and limitations, such as relatively poor heat resistance and susceptibility to aging. During use, corresponding protective measures should be taken according to specific application scenarios, such as adding heat-resistant agents, antioxidants, etc., to extend their service life and fully leverage their advantages.

Lubricant decomposition

- Compound: How to use elastin

In the introduction section, elastin is a protein that plays a crucial role in the body, endowing tissues with elasticity and toughness. Its properties include high elasticity and good ductility. Elastin has a wide range of sources and is commonly found in animal connective tissues such as skin and blood vessels. When using elastin in products, the amount and method of addition should be determined based on the characteristics of the product. It has many uses and can be added to skincare products to enhance skin elasticity and reduce wrinkles; Improving food texture and enhancing taste in the food industry; In the medical field, it can be used to make elastic scaffolds such as artificial blood vessels, providing support for tissue repair. Reasonable use can play its unique value.

- Compound: Instructions for using protein

This document aims to guide the proper use of proteins. Proteins are the fundamental substances that make up life and are essential for maintaining normal physiological functions in the body, with a wide variety of types. When using protein, daily diet is an important source, such as meat, eggs, etc., which are rich in high-quality protein. Measuring protein intake can be done using professional tools or methods to ensure that the intake meets the body's needs. When mixing protein powder, it should be prepared according to the recommended ratio, and the water temperature should not be too high to avoid damaging the protein activity. Different groups of people have different protein requirements, such as athletes and fitness enthusiasts who can increase their intake appropriately to meet the needs of body repair and muscle growth.

- Compound: Usage of Unsaturated Polyester Resin

Introduction to Unsaturated Polyester Resin: It is an important thermosetting resin with various excellent properties. It has a wide range of applications and is used in the construction industry to produce fiberglass products such as doors, windows, decorative panels, etc; Used in the automotive industry for manufacturing body components. The advantages of use include simple molding process, low cost, and chemical corrosion resistance. However, it also faces challenges and limitations, such as relatively poor heat resistance and susceptibility to aging. During use, corresponding protective measures should be taken according to specific application scenarios, such as adding heat-resistant agents, antioxidants, etc., to extend their service life and fully leverage their advantages.

- Recommended to you

- Outline

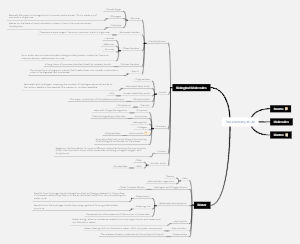

Lubricant decomposition

Definition

Chemical breakdown

Alteration of chemical structure

Loss of original properties

Change in viscosity

Loss of lubricity

Formation of new compounds

Potentially harmful substances

Environmental factors

Temperature

High temperatures accelerate decomposition

Low temperatures may slow down the process

Oxygen exposure

Oxidation as a common cause

Formation of peroxides and acids

Light exposure

Photochemical reactions

Degradation of additives

Physical breakdown

Shear forces

Mechanical stress

Frictional heat generation

Wear and tear of machinery

Cavitation

Formation and collapse of vapor bubbles

Localized pressure changes

Emulsification

Water contamination

Formation of waterinoil emulsions

Causes

Inherent instability

Poor base oil quality

Presence of unstable hydrocarbons

Susceptibility to thermal and oxidative stress

Low additive stability

Inadequate protection against decomposition

Incorrect formulation

Lack of necessary additives

Inadequate antioxidant levels

Use of incompatible additives

Chemical interactions leading to decomposition

External factors

Contamination

Water ingress

Hydrolysis of esters and other compounds

Particulate matter

Abrasive wear accelerating breakdown

Chemicals

Reaction with incompatible substances

Operational conditions

Excessive load

Increased mechanical stress on lubricant

Extended service intervals

Prolonged exposure to stress factors

Consequences

Equipment damage

Increased wear rates

Surface degradation

Roughening of contact surfaces

Corrosion

Metal surfaces exposed to corrosive byproducts

Reduced efficiency

Loss of power

Higher energy consumption

Increased maintenance costs

Frequent lubricant changes

Repairs and replacements

Safety hazards

Toxic byproducts

Formation of harmful chemicals

Risk to personnel health

Fire and explosion risks

Combustible decomposition products

Increased flammability of lubricant

Prevention and mitigation

Regular monitoring

Oil analysis

Detection of early signs of decomposition

Spectrometric analysis

Viscosity measurements

Trend analysis

Predictive maintenance

Conditionbased maintenance

Scheduled changes

Proactive replacement of lubricants

Realtime monitoring

Use of sensors for immediate alerts

Proper lubricant selection

Matching lubricant to application

Considering operating conditions

Temperature, load, and speed

Choosing stable formulations

Highquality base oils and additives

Control of operational factors

Limiting exposure to stressors

Temperature control

Cooling systems to maintain optimal temperatures

Avoiding contamination

Use of filters and seals

Regular cleaning of machinery

Maintenance of machinery

Regular inspections

Early detection of wear and tear

Proper lubrication techniques

Correct application methods

Avoiding overlubrication or underlubrication